10-K: Annual report pursuant to Section 13 and 15(d)

Published on March 13, 2015

UNITED STATES SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

(Mark One)

[ X ] ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the Fiscal Year Ended December 31, 2014

or

[ ] TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934

For the transition period from ……………… to ………………

Commission file number 000-03922

PATRICK INDUSTRIES, INC.

(Exact name of registrant as specified in its charter)

|

INDIANA |

35-1057796 |

|

(State or other jurisdiction of |

(I.R.S. Employer |

|

incorporation or organization) |

(Identification No.) |

| 107 W. FRANKLIN STREET, P.O. Box 638, ELKHART, IN | 46515 |

| (Address of principal executive offices) | (Zip Code) |

(574) 294-7511

(Registrant’s telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

|

Common stock, without par value (Title of each class) |

Nasdaq Stock Market LLC (Name of each exchange on which registered) |

Securities registered pursuant to Section 12(g) of the Act: None

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. Yes [ ] No [X]

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange Act. Yes [ ] No [X]

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. Yes [X] No [ ]

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). Yes [X] No [ ]

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of registrant’s knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. [ ]

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act. Large accelerated filer [ ] Accelerated filer [X] Non-accelerated filer [ ] (Do not check if a smaller reporting company) Smaller reporting company [ ]

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Act). Yes [ ] No [X]

The aggregate market value of the voting stock held by non-affiliates of the registrant on June 27, 2014 (based upon the closing price on the Nasdaq Stock Market LLC and an estimate of 70.15% of shares owned by non-affiliates) was $328,084,901. The closing market price was $44.19 on that day and 10,583,628 shares of the registrant’s common stock were outstanding. As of February 27, 2015, there were 10,283,901 shares of the registrant’s common stock outstanding.

DOCUMENTS INCORPORATED BY REFERENCE

Portions of the registrant’s Proxy Statement for its Annual Meeting of Shareholders to be held on May 19, 2015 are incorporated by reference into Part III of this Form 10-K.

PATRICK INDUSTRIES, INC.

FORM 10-K

FISCAL YEAR ENDED DECEMBER 31, 2014

TABLE OF CONTENTS

|

PART I |

3 |

|

|

ITEM 1. |

BUSINESS |

3 |

|

ITEM 1A. |

RISK FACTORS |

14 |

|

ITEM 1B. |

UNRESOLVED STAFF COMMENTS |

21 |

|

ITEM 2. |

PROPERTIES |

22 |

|

ITEM 3. |

LEGAL PROCEEDINGS |

23 |

|

ITEM 4. |

MINE SAFETY DISCLOSURES |

23 |

|

PART II |

23 |

|

|

ITEM 5. |

MARKET FOR REGISTRANT’S COMMON EQUITY, RELATED STOCKHOLDER MATTERS, AND ISSUER PURCHASES OF EQUITY SECURITIES |

23 |

|

ITEM 6. |

SELECTED FINANCIAL DATA |

26 |

|

ITEM 7. |

MANAGEMENT’S DISCUSSION AND ANALYSIS OF FINANCIAL CONDITION AND RESULTS OF OPERATIONS |

26 |

|

ITEM 7A. |

QUANTITATIVE AND QUALITATIVE DISCLOSURES ABOUT MARKET RISK |

48 |

|

ITEM 8. |

FINANCIAL STATEMENTS AND SUPPLEMENTARY DATA |

48 |

|

ITEM 9. |

CHANGES IN AND DISAGREEMENTS WITH ACCOUNTANTS ON ACCOUNTING AND FINANCIAL DISCLOSURE |

48 |

|

ITEM 9A. |

CONTROLS AND PROCEDURES |

49 |

|

ITEM 9B. |

OTHER INFORMATION |

49 |

|

PART III |

50 |

|

|

ITEM 10. |

DIRECTORS, EXECUTIVE OFFICERS AND CORPORATE GOVERNANCE |

50 |

|

ITEM 11. |

EXECUTIVE COMPENSATION |

50 |

|

ITEM 12. |

SECURITY OWNERSHIP OF CERTAIN BENEFICIAL OWNERS AND MANAGEMENT AND RELATED STOCKHOLDER MATTERS |

51 |

|

ITEM 13. |

CERTAIN RELATIONSHIPS AND RELATED TRANSACTIONS, AND DIRECTOR INDEPENDENCE |

51 |

|

ITEM 14. |

PRINCIPAL ACCOUNTING FEES AND SERVICES |

51 |

|

PART IV |

51 |

|

|

ITEM 15. |

EXHIBITS AND FINANCIAL STATEMENT SCHEDULES |

51 |

|

SIGNATURES |

55 |

FINANCIAL SECTION

|

Index to Financial Statements and Financial Statement Schedules |

F-1 |

|

|

Report of Independent Registered Public Accounting Firm, Crowe Horwath LLP |

F-2 |

|

|

Consolidated Statements of Financial Position |

F-3 |

|

|

Consolidated Statements of Income |

F-4 |

|

|

Consolidated Statements of Comprehensive Income |

F-5 |

|

|

Consolidated Statements of Shareholders’ Equity |

F-6 |

|

|

Consolidated Statements of Cash Flows |

F-7 |

|

|

Notes to Consolidated Financial Statements |

F-8 |

|

|

Exhibits |

|

INFORMATION CONCERNING FORWARD-LOOKING STATEMENTS

This Form 10-K contains certain “forward-looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995 with respect to financial condition, results of operations, business strategies, operating efficiencies or synergies, competitive position, industry growth and projections, growth opportunities for existing products, plans and objectives of management, markets for the common stock of Patrick Industries, Inc. (collectively, the “Company,” “we,”, “our” or “Patrick”) and other matters. Statements in this Form 10-K as well as other statements contained in the annual report and statements contained in future filings with the Securities and Exchange Commission (“SEC”) and publicly disseminated press releases, and statements which may be made from time to time in the future by management of the Company in presentations to shareholders, prospective investors, and others interested in the business and financial affairs of the Company, which are not historical facts, are forward-looking statements that involve risks and uncertainties that could cause actual results to differ materially from those set forth in the forward-looking statements. Patrick does not undertake to publicly update or revise any forward-looking statements, except as required by law. You should consider forward-looking statements, therefore, in light of various important factors, including those set forth in the reports and documents that the Company files with the SEC, including this Annual Report on Form 10-K for the year ended December 31, 2014.

There are a number of factors, many of which are beyond the control of the Company, which could cause actual results and events to differ materially from those described in the forward-looking statements. Many of these factors are identified in the “Risk Factors” section of this Form 10-K as set forth in Part I, Item 1A. These factors include, without limitation, the impact of any economic downturns especially in the residential housing market, a decline in consumer confidence levels, pricing pressures due to competition, costs and availability of raw materials, availability of commercial credit, availability of retail and wholesale financing for residential and manufactured homes, availability and costs of labor, inventory levels of retailers and manufacturers, levels of repossessed residential and manufactured homes, the financial condition of our customers, retention and concentration of significant customers, the ability to generate cash flow or obtain financing to fund growth, future growth rates in the Company's core businesses, the seasonality and cyclicality in the industries to which our products are sold, the ability to effectively manage the costs and the implementation of the new enterprise resource management system, the successful integration of acquisitions, interest rates, oil and gasoline prices, adverse weather conditions impacting retail sales, and our ability to remain in compliance with our credit agreement covenants. In addition, national and regional economic conditions and consumer confidence may affect the retail sale of recreational vehicles and residential and manufactured homes.

Any projections of financial performance or statements concerning expectations as to future developments should not be construed in any manner as a guarantee that such results or developments will, in fact, occur. There can be no assurance that any forward-looking statement will be realized or that actual results will not be significantly different from that set forth in such forward-looking statement. See Part I, Item 1A “Risk Factors” below for further discussion.

PART I

|

ITEM 1. |

BUSINESS |

Company Overview

Patrick Industries, Inc., which was founded in 1959 and incorporated in Indiana in 1961, is a major manufacturer of component products and distributor of building products and materials for the recreational vehicle (“RV”) and manufactured housing (“MH”) industries. In addition, we are a supplier to certain other industrial markets, such as kitchen cabinet, office and household furniture, fixtures and commercial furnishings, marine, and other industrial markets. We manufacture a variety of products including decorative vinyl and paper laminated panels, fabricated aluminum products, wrapped vinyl, paper and hardwood profile mouldings, solid surface, granite and quartz countertops, cabinet doors and components, hardwood furniture, fiberglass bath and shower fixtures, fiberglass and plastic component products including front and rear caps and marine helms, slide-out trim and fascia, interior passage doors, exterior graphics and RV painting, simulated wood and stone products, and slotwall panels and components, among others.

We are also an independent wholesale distributor of pre-finished wall and ceiling panels, drywall and drywall finishing products, electronics, wiring, electrical, and plumbing products, cement siding, fiber reinforced polyester (“FRP”) products, interior passage doors, roofing products, laminate and ceramic flooring, shower doors, furniture, fireplaces and surrounds, interior and exterior lighting products, and other miscellaneous products. We have a nationwide network of manufacturing and distribution centers for our products, thereby reducing in-transit delivery time and cost to the regional manufacturing plants of our customers. We believe that we are one of the few suppliers to the RV and MH industries that has such a nationwide network. We maintain 25 manufacturing plants and nine distribution facilities near our principal offices in Elkhart, Indiana, and operate seven other warehouse and distribution centers and seven other manufacturing plants in nine other states.

Approximately 84% and 91% of our consolidated net sales in 2014 and 2013, respectively, were decorative interior products and components, consisting primarily of manufactured panels, mouldings and trim, hardwood and pressed doors, furniture and fascia, countertops, and fiberglass products. We have no material patents, licenses, franchises, or concessions and do not conduct significant research and development activities.

Over the past several years, we have executed on a number of strategic initiatives including: the completion of 17 acquisitions and the introduction of over 260 new products and product line extensions (2010 through February 2015), the implementation of a branding strategy, increasing our market share, deleveraging our balance sheet, investing in property, plant and equipment, operational restructuring at certain manufacturing and distribution facilities, disposition of underperforming operations and facilities, aggressive management of inventory levels to changes in sales levels, and amending and refinancing our credit facility to provide continued capacity to execute on our strategic plan. The combination of improving economic conditions, particularly in the RV industry, and the execution of the strategic initiatives identified above, among others, resulted in our sales, operating income, net income and cash flows improving significantly in the four years ended December 31, 2014. In the Executive Summary section of Item 7, “Management’s Discussion and Analysis of Financial Condition and Results of Operations,” we provide an overview of the impact that macroeconomic conditions had on our operations and in the RV, MH and industrial markets in 2014.

We have continued to expand the breadth and the depth of our products and services through the integration of new and innovative product lines designed to bring value to our customers and create additional scale advantages. See “Strategic Acquisitions and Expansion” below and Note 4 to the Consolidated Financial Statements in Item 8 of this report for further details.

Patrick had two reportable operating segments in 2014, Manufacturing and Distribution. Financial information about these operating segments is included in Note 19 to the Consolidated Financial Statements and incorporated herein by reference.

Competitive Position

The RV and MH industries are highly competitive with low barriers to entry, which carries through to the suppliers to these industries. Across the Company’s range of products and services, competition exists primarily on price, product features, quality, and service. Several competitors compete in each product line with us on a regional and local basis. However, in order for a competitor to compete with us on a national basis, we believe that a substantial capital commitment and investment in personnel and facilities would be required. The industrial markets that we serve are also highly competitive.

Given the environment in the industries in which we operate, the Company has identified several operating strategies to maintain or enhance earnings through strategic acquisitions, productivity initiatives, expansion into new product lines, and optimization of capacity utilization.

Strategy

Overview

We believe that we have developed strong working relationships with our customers and suppliers, and have oriented our business to their needs. Our customers include all of the larger RV and MH manufacturers and a number of large to medium-sized industrial customers. The majority of our industrial customers are generally directly linked to the residential housing markets. Our RV and MH customers generally demand competitive prices, high quality standards, short lead times, and a high degree of flexibility from their suppliers. Our industrial customers generally are less price sensitive than our RV and MH customers, and are focused on consistent high quality products, exceptional customer service, and quick response time.

Our capital allocation strategy includes a balance of managing and utilizing our resources and leverage position to continue to grow and invest in the business model through strategic acquisitions, investment in infrastructure and capital expenditures to ensure both capacity and technology to support anticipated growth needs, and stock repurchases, among others. Additionally, because of the short lead times, which can include same day order, receipt and delivery, we continue to focus on managing our inventory levels to achieve a balance between increasing inventory turns and ensuring we have product on hand to meet customer demand levels.

As we explore new markets and industries, we believe that our core competencies and focus on executing on our strategic plan provide us with a strong foundation for future growth. In 2014, approximately 74% of our net sales were to the RV industry, 15% to the MH industry, and 11% to the industrial markets. In 2013, approximately 72% of our net sales were to the RV industry, 16% to the MH industry, and 12% to the industrial markets. The increase in wholesale unit shipments in the RV market relative to the other primary market sectors in which Patrick operates, the introduction of new products to the marketplace, and the impact of the acquisitions completed in the last five years, have led to an increase in our RV market sales concentration through 2014 when compared to prior periods.

Operating Strategies

Key operating strategies identified by management include the following:

Strategic Acquisitions and Expansion

We supply a broad variety of building materials and component products to the RV, MH and industrial markets. With our nationwide manufacturing and distribution capabilities and capacities, we believe that we are well positioned for continued market improvement in all industry sectors and the introduction of new products to further bring value to our customer base. In order to facilitate this initiative, we are focused on driving growth in all three of our primary markets through the acquisition of companies with strong management teams with a strategic fit to our core values, business model and customer presence, as well as additional product lines, facilities, or other assets to complement or expand our existing businesses. We believe there continues to be acquisition opportunities in all three primary markets that we serve.

From 2010 to 2012, we invested approximately $43 million, in the aggregate, to complete a total of nine acquisitions, which directly complemented our core competencies and product lines.

In 2013, we invested approximately $17 million to complete three acquisitions: Frontline Mfg., Inc. (“Frontline”), a manufacturer of fiberglass bath fixtures, including tubs, showers and combination tub/shower units for the RV, MH and residential housing markets; Premier Concepts, Inc. (“Premier”), a custom fabricator of solid surface, granite, and quartz countertops for the RV, MH and residential housing markets; and John H. McDonald Co., Inc. d/b/a West Side Furniture (“West Side”), a wholesale supplier of La-Z-Boy® recliners and the Serta® Trump Home™ mattress line, among other furniture products, to the RV market.

In 2014, we invested approximately $72 million to complete four acquisitions: Precision Painting, Inc., Carrera Custom Painting, Inc., and Millennium Paint, Inc., three related full service exterior full body painting operations that offer exterior painting and interior refurbishing for both OEMs and existing RV and fleet owners, and TDM Transport, Inc., a transportation operation that services their in-house customers (collectively referred to as “Precision Painting Group” or “Precision”); Foremost Fabricators, LLC (“Foremost”), a fabricator and distributor of fabricated aluminum products, FRP sheet and coil, and custom laminated products primarily used in the RV market; PolyDyn3, LLC (“PolyDyn3”), a custom fabricator of simulated wood and stone products for the RV market; and Charleston Corporation (“Charleston”), a manufacturer of fiberglass and plastic components primarily used in the RV, marine, and vehicle aftermarket industries. See Note 4 to the Consolidated Financial Statements.

In February 2015, we invested approximately $40 million to acquire Better Way Partners, LLC d/b/a Better Way Products (“Better Way”), a manufacturer of fiberglass front and rear caps, marine helms and related fiberglass components.

Diversification into Other Markets

While we continually seek to improve our position as a leading supplier to the RV and MH industries, we are also seeking to expand our product lines into other industrial, commercial, and institutional markets. Many of our products, such as countertops, hardwood and pressed cabinet doors, laminated panels and mouldings, drawer sides and fronts, slotwall, and shelving, have applications in the kitchen cabinet, retail fixtures, household furniture, and architectural markets. We have a dedicated sales force focused on increasing our industrial market penetration and on our diversification into additional commercial and institutional markets.

We believe that diversification into other industrial markets provides opportunities for improved operating margins with complementary products that increase our capacity utilization. In addition, we believe that our nationwide manufacturing and distribution capabilities have enabled us to be well positioned for new product expansion.

Additionally, we may explore strategic acquisition opportunities that are not directly tied to the three primary markets we serve in order to further leverage our core competencies in manufacturing and distribution and to diversify our end market exposure and presence.

Utilization of Manufacturing Capacity

Efficiency Optimization

We have the ability to increase revenues in all of our existing facilities without adding comparable incremental fixed costs. If economic conditions in certain parts of the country warrant, we will explore opportunities for further facility consolidation. However, we have remained committed to certain geographic areas, specifically where there is a larger concentration of MH manufacturers but where our revenues and profitability have been constrained in recent years. Additionally, we are focused on cross-training all of our manufacturing work force in our manufacturing cells within each facility to maximize our efficiencies and increase the flexibility of our labor force.

Plant Consolidations / Closures and Plant Expansion

Certain manufacturing and distribution operating facilities were either consolidated or expanded during 2013 and 2014 in an effort to continue to improve operating efficiencies in the plants through increased capacity utilization. In 2013, we purchased one of our distribution facilities that we had previously been leasing from an unrelated third party and leased additional facilities to accommodate larger inventory levels and growth in our manufacturing and distribution businesses. In 2014, we closed our leased distribution facility in Madisonville, Tennessee and consolidated the business into the existing Mt. Joy, Pennsylvania and Decatur, Alabama distribution facilities that engage in similar activities.

Product Development and New Product Introductions/Discontinuations

With our versatile manufacturing and distribution capabilities, we are continually striving to increase our presence in all of the markets that we serve and gain entrance into other markets. We remain committed to new product introduction and development initiatives. New product development is a key component of our strategy to grow our market share and revenue base, keep up with changing market conditions, and proactively address customer demand. We have a design center featuring our major product lines and a specialized design team that works exclusively with RV and MH manufacturers to meet their creative design and product needs including creating new styles and utilizing new colors, patterns, products, and wood types for panels and mouldings, cabinet doors, furniture, lighting and other products. We will continue to focus our time and attention to manufacturing and distributing products that fit within the strategic parameters of our current business model, including appropriate margin and inventory turn levels.

In addition to the new product offerings stemming from acquisitions, we further enhanced our product offerings to our customers in the RV, MH, and industrial markets through the introduction of several new products and the expansion of our existing product lines in 2014 including, on the manufacturing side, several new cabinet door styles, upgraded cabinetry and countertops, new slide-out trim, new styles of interior passage doors for RVs, pressed countertops, lighting packages, backsplashes and exterior graphics and paint. Our distribution line of products was expanded to include new faucets modeled after the residential market, residential furniture, televisions and sound bars, ceramic tile, flat-pack cabinets, power cords, flooring options and various building products.

Branding

In conjunction with our acquisition strategy, we continue to focus our efforts on providing specific product knowledge, expertise and support to our customers through a branding strategy which includes product managers for each of our key product lines, support staff, and strategic supplier relationships which allows us to partner with them as a supplier of choice to drive efficiency and maximize value by providing the expertise and product support in the products that we sell. Our primary product brands include Adorn, Custom Vinyls, Patrick Distribution, AIA Countertops, Quest Audio Video, Interior Components Plus, Gravure Ink, Praxis Group, Infinity Graphics, Décor Manufacturing, Gustafson Lighting, Creative Wood Designs, Middlebury Hardwood Products, Frontline Manufacturing, Premier Concepts, West Side Furniture, Precision Painting, Carrera Custom Painting, Millennium Paint, Foremost Fabricators, PolyDyn3, Charleston and Better Way Products. In addition, our industrial markets sector cross sells existing product lines and launches new products that are targeted to serve unique, consumer-driven channels under the Decorative Dynamics brand name.

Manufacturing Processes and Operations

Our lamination facilities utilize various materials such as lauan, medium-density fiberboard (“MDF”), gypsum, and particleboard, which are bonded by adhesives or a heating process to a number of products, including vinyl, paper, foil, and high-pressure laminates. Additionally, we offer high-pressure laminate bonded primarily to particleboard, which has many uses, including countertops, cabinetry, and office furniture, among others. We manufacture and fabricate solid surface, granite, quartz, and high-pressure laminate countertops for all of our primary markets, as well as slotwall panels and components for the retail store fixture markets. Roll-laminated products are used in the production of wall, cabinet, shelving, counter, and fixture products with a wide variety of finishes and textures. In conjunction with our manufacturing capabilities, we also provide value added processes, including custom fabrication, edge-banding, drilling, boring, and cut-to-size capabilities. We also manufacture various fiberglass bath and shower surrounds and fixtures.

We manufacture three distinct cabinet door product lines in both raised and flat panel designs, as well as square, shaker style, cathedral and arched panels. Our primary cabinet door product line is manufactured from raw lumber using solid oak, maple, cherry and other hardwood materials, and comes in a variety of finishes and glazes. Another line of doors is made of laminated fiberboard, and a third line uses membrane press technology to produce doors and components with vinyls of various thicknesses. Doors are also made with a number of outside decorative components such as rosettes, hardwood moulding, arched window trim, blocks and windowsills, among others. Our doors are sold mainly to the RV and MH industries. We also market to the cabinet manufacturers and “ready-to-assemble” furniture manufacturers.

Our vinyl printing facility produces a wide variety of decorative and textured vinyls, which are generally 50” in width and 3.2 mil nominal thickness, and are shipped in rolls ranging from 300-800 yards in length. This facility produces material both for sale to external customers and for internal use.

In 2014, we expanded our stable of products to the markets we serve with the acquisition of three related exterior full body painting operations (the Precision Group), a fabricator and distributor of fabricated aluminum and FRP products (Foremost), a custom fabricator of simulated wood and stone products (PolyDyn3), and a manufacturer of fiberglass and plastic components (Charleston). In February 2015, we acquired the operations of Better Way, a custom fiberglass fabricator for the RV, marine and transit vehicle markets.

Markets

We are engaged in the manufacturing and distribution of building products and material for use primarily by the RV and MH industries, and in other industrial markets. We continue to capture market share through our strategic acquisitions and new product initiatives, which have resulted in sales levels growing at a rate in excess of the general industry over the last five years.

Over the past five years, industry conditions in the RV industry have continued to improve as evidenced by higher production levels and wholesale unit shipments versus the prior year periods. We believe that industry-wide retail sales and the related production levels of RVs will be dependent on the overall strength of the economy, consumer confidence levels, conditions in the credit markets, and other demographic trends. Recreational vehicle purchases are generally consumer discretionary income purchases, and therefore, any situation which causes concerns related to discretionary income can have a negative impact on this market.

The MH industry, which has improved marginally in recent years, continues to be negatively impacted by the lack of financing alternatives and credit availability, and in certain areas, excess residential housing inventories. Financing concerns and the current credit situation in the residential housing market have put additional pressure on potential purchasers of manufactured homes, many of whom use conventional mortgage financing as a source of funding for purchases. While there is still overhang related to the overall economic environment and other conditions mentioned above, we believe that there is upside potential and limited risk as it relates to residential housing growth based on pent up demand, job growth, the availability of credit, and affordable interest rates. On average over the last 40 years, approximately three-fourths of total residential housing starts have been single-family housing starts. In addition, wholesale unit shipment levels in the MH industry have averaged approximately 9% to 11% of the level of single-family housing starts over the last 10 years.

Approximately 56% of our industrial revenue base in 2014 was associated with the U.S. residential housing market, and therefore, there is a direct correlation between the demand for our products in this market and new residential housing construction and remodeling activities.

In order to offset some of the impacts of the weakness in the residential housing market over the last several years, we have focused on diversification, strategic acquisitions, and bringing new and innovative products to the market. In addition, we have targeted certain sales efforts towards market segments that are less directly tied to residential new home construction, including the retail fixture, furniture, and countertop markets. As a result, we have seen a shift in our product mix, which has had a positive impact on revenues from the industrial markets. Additionally, we have gained market share and expanded into new geographic territories as a result of investment in new team members with significant product knowledge, relationships, and expertise in the commercial markets.

Recreational Vehicles

The RV industry has been characterized by cycles of growth and contraction in consumer demand, reflecting prevailing general economic conditions, which affect disposable income for leisure time activities. The deeper cycles have been tied to major economic and world events including the Gulf War, the September 11, 2001 terrorist attacks, and the “Great Recession” of 2007-2009. We believe that consumer confidence, the level of disposable income, equity securities market trends, and significant fluctuations in interest rates have an impact on RV sales. Over the past several years, however, we believe there has been a level of resilience in the RV marketplace, where RV buyers appear to have prioritized the purchase of a unit over other discretionary items in an effort to pursue their desired “RV lifestyle”. While concerns about the availability and price of gasoline can have an impact on RV demand, market trends also indicate that the average RV owner travels less distance but with similar frequency during periods of higher gas prices and less availability. Periods of lower gasoline prices can have a positive impact on RV retail purchases, however extended periods of lower fuel prices followed by a sudden increase in prices could have a negative impact on retail RV purchases in the short term while the market adjusts.

Demographic and ownership trends continue to point to favorable market growth in the long-term, both as the number of “baby-boomers” reaching retirement is steadily increasing, and as the RV owning population in the 35-54 year old demographic continues to grow. The U.S. Census Bureau estimates that there are expected to be approximately 10,000 “baby-boomers” reaching age 65 every day through 2029. Additionally, products such as sports-utility RVs and “toy haulers,” with a rear section to store and transport motorcycles, snowmobiles, ATVs, sand rails, and other leisure products, are attractive to younger buyers, and RV manufacturers are also providing an array of product choices, including producing lightweight towables and smaller fuel efficient motorhomes. Green technologies, such as lightweight composite materials, solar panels, and energy-efficient components are also options that can be added to an RV.

Recreational vehicle classifications are based upon standards established by the Recreational Vehicle Industry Association (“RVIA”). The principal types of recreational vehicles include: (1) Towables: conventional travel trailers, folding camping trailers, fifth wheel trailers, and truck campers which are lighter and less expensive than standard gas or diesel powered motorized units, representing a more attractive solution for the cost-conscious buyer; and (2) Motorized: motor homes. Both towable and motorized RV units are distinct from mobile homes, which are manufactured houses designed for permanent and semi-permanent residential dwelling. The Company estimates that its mix of RV revenues related to towable units and motorized units is consistent with the overall RV production mix. In both 2014 and 2013, towable and motorized unit shipments represented approximately 88% and 12%, respectively, of total RV wholesale shipments. Towable unit shipments increased approximately 11% and 10%, respectively, while motorized unit shipments rose approximately 15% and 36% in the comparable periods.

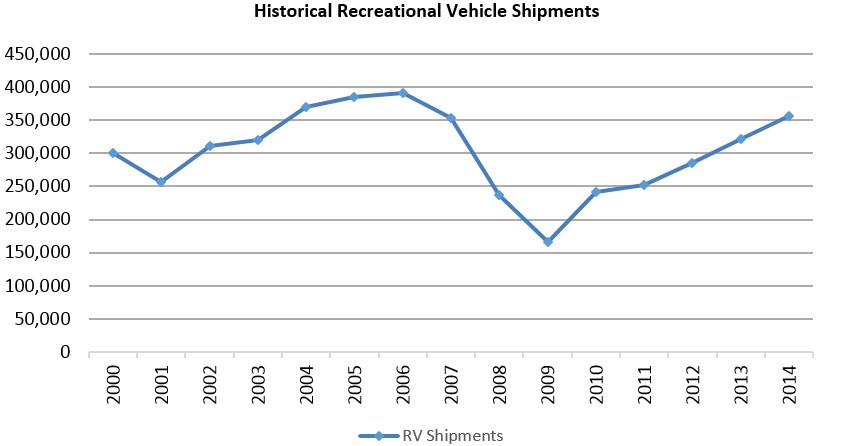

Sales of recreational vehicle products have been cyclical in the past. In the most recent major cycle, wholesale unit shipments in the RV industry declined from an all-time high of 390,500 units in 2006 to 165,700 units in 2009. The RV industry began to improve in the latter half of 2009 and into 2010 with shipment levels in 2010 increasing 46% from those in 2009. Unit shipment levels reached 321,127 units in 2013, which was the first time that shipment levels rose above 300,000 units since 2007. In 2014, shipment levels rose 11% to 356,735 units, resulting in a cumulative gain of approximately 115% since 2009. The RVIA is currently forecasting full year 2015 wholesale unit shipments to increase by approximately 6% compared to the 2014 level.

The following chart reflects historical wholesale unit shipment levels in the RV industry from 2000 through 2014 per RVIA statistics:

Manufactured Housing

Manufactured homes historically have been one of the principal means for first-time homebuyers to overcome the obstacles of large down payments and higher monthly mortgage payments due to the lower cost of construction as compared to site-built homes. Manufactured housing also provides a cost effective alternative for those individuals and families seeking to establish home ownership or whose credit ratings have been impacted by the economic and job environment over the past several years. In addition, manufactured homes are an attractive option for those who have migrated to temporary and multi-family housing alternatives, an attractive entry point for many first-time homebuyers and individuals and families looking to re-enter the homeownership market, or for retirees and others desiring a lifestyle in which home ownership is less burdensome than in the case of site-built homes.

Manufactured homes are constructed to the building standards of the U.S. Department of Housing and Urban Development (“HUD”) and are factory built and transported to a site where they are installed, often permanently. Some manufactured homes have design limitations imposed by the constraints of efficient production and over-the-road transit. Delivery expense limits the effective competitive shipping range of the manufactured homes to approximately 400 to 600 miles. Modular homes, which are built in accordance with state and local building codes, are factory built homes that are built in sections and transported to the site for installation. These homes and many HUD code homes are generally set on a foundation and are subject to land/home-financing terms and conditions.

The MH industry is affected by the availability, cost, and in many cases the credit requirements of alternative housing, such as apartments, town houses, condominiums and site-built housing, including repossessed residential housing inventory levels. From 1998 to 2009, annual industry-wide wholesale unit shipments of manufactured homes declined 87%. The 2009 level of 49,789 wholesale units was at the lowest level in the last 50 years. From the period of 2009-2013, MH unit shipments rose 21%. In 2014, MH unit shipments rose 7% but continued to trend well below historical levels.

Sales growth in the MH industry continues to be limited by the lack of financing alternatives and credit availability, and in certain geographic areas, excess residential housing inventories. While we do not anticipate significant growth in the MH market in 2015, we believe that there is opportunity for moderate growth with limited downside risk in the near-term, and more significant growth in the longer-term assuming improved availability of credit and recalibration of quality credit standards.

Factors that may favorably impact production levels further in this industry include quality credit standards in the residential housing market, favorable changes in financing regulations, higher interest rates on traditional residential housing loans, and improved conditions in the asset-backed securities markets for manufactured housing loans. While there is still some overhang related to the overall economic environment and other conditions mentioned above, we believe that there is also longer term potential for this industry as residential housing demand continues to improve. On average over the last 40 years, approximately three-fourths of total residential housing starts have been single-family housing starts. In addition, wholesale unit shipment levels in the MH industry have averaged approximately 9% to 11% of the level of single-family housing starts over the last 10 years.

The following chart reflects the historical wholesale unit shipment levels in the MH industry from a recent high in 2000 through 2014 per the Manufactured Housing Institute:

Other Markets

Many of our core manufacturing products, including paper/vinyl laminated panels, shelving, drawer-sides, high-pressure laminated panels, solid surface, granite, and quartz countertops, cut to size products, and fiberglass and plastic components are utilized in the kitchen cabinet, office and household furniture, fixtures and commercial furnishings, marine, and other industrial products markets. These markets are generally categorized by a more performance-than-price driven customer base, and provide an opportunity for us to diversify our customer base, while providing increased contribution to our core laminating and fabricating competencies. While the residential furniture markets have been impacted by import pressures, there has been a renewed interest in domestically produced products and the “Made in the USA” label. Additionally, other residential and commercial segments have been less vulnerable to import competition, and therefore provide opportunities for increased sales penetration and market share gains. Over the past three years, the residential housing market in particular has shown signs of improving across the country and that trend is expected to continue in fiscal 2015 resulting in increased demand for our products. Our sales to the industrial market generally lag new housing starts by six to nine months and will vary based on differences in regional economic prospects. We believe that we have the available capacity to increase industrial revenue and benefit from the diversity of multiple market segments, unique regional economies and varied customer strategies.

Marketing and Distribution

Our sales are to RV and MH manufacturers and other industrial products manufacturers. We have over 800 active customers. We have five customers that together accounted for approximately 67% and 66% of our consolidated net sales in 2014 and 2013, respectively. The Company's RV products include consolidated sales to two major manufacturers of RVs who each account for over 10% of consolidated net sales - Forest River, Inc. (a Berkshire Hathaway Company) (“Forest River”) and Thor Industries, Inc. (stock symbol: THO) (“Thor”). Both Forest River and Thor are comprised of various operating subsidiaries and brand names that operate within the parent company. For the years ended December 31, 2014 and 2013, our combined sales to the operating subsidiaries of Forest River and Thor, on a consolidated basis, accounted for 58% and 57% of our consolidated net sales, respectively.

A majority of products for distribution are generally purchased in railcar, container, or truckload quantities, warehoused, and then sold and delivered by us. In addition, approximately 18% and 23% of our distribution segment’s sales were from products shipped directly from the suppliers to our customers in 2014 and 2013, respectively. We typically experience a one to two week delay between issuing our purchase orders and the delivery of products to our warehouses or customers. We generally keep backup supplies of various commodity products in our warehouses to ensure that we have product on hand at all times for our distribution customers. Our customers do not maintain long-term supply contracts, and therefore we must bear the risk of accurate advanced estimation of customer orders. In periods of declining market conditions, customer order rates can decline, resulting in less efficient logistics planning and fulfillment and thus increasing delivery costs due to increased numbers of shipments with fewer products in each shipment. We have no significant backlog of orders.

With the acquisitions completed in 2014 and certain plant consolidations, we operate 16 warehouse and distribution centers and 32 manufacturing operations located in Alabama, Arizona, California, Georgia, Illinois, Indiana, Minnesota, Oregon, Pennsylvania, and Texas. By using these facilities, we are able to minimize our in-transit delivery time and cost to the regional manufacturing plants of our customers.

Patrick does not engage in significant marketing efforts nor does it incur significant marketing or advertising expenditures, other than attendance at certain trade shows and the activities of its sales personnel and the maintenance of customer relationships through price, quality of its products, service and customer satisfaction. In our design showroom located in Elkhart, Indiana, many of our manufactured and distribution products are on display for current and potential customers, their design and purchasing staff, and other key product managers and designers. We believe the design showroom provides additional opportunities to add value for our customers by allowing them to experience our large range of product offerings and related style and content options that we have available, as well as offering in-house custom design services to further differentiate our product lines. In addition, our Company website, www.patrickind.com, has allowed us to expand our Internet presence and further showcase our primary product brands to both existing and potential customers.

Suppliers

During the year ended December 31, 2014, we purchased approximately 52% of our raw materials and distributed products from twenty different suppliers. The five largest suppliers accounted for approximately 28% of our total purchases. We have terms and conditions with certain suppliers that specify exclusivity in certain areas, pricing structures, rebate agreements and other parameters.

Raw materials are primarily commodity products, such as lauan, gypsum, particleboard, other lumber products, resin, and overlays, among other which are available from many suppliers. We do not maintain long-term supply agreements. Our sales in the short-term could be negatively impacted in the event any unforeseen negative circumstances were to affect our major suppliers. We believe that we have a good relationship with all of our suppliers. Alternate sources of supply are available for all of our material purchases.

Regulation and Environmental Quality

The Company’s operations are subject to certain federal, state, and local regulatory requirements relating to the use, storage, discharge and disposal of hazardous chemicals used during their manufacturing processes. Over the past several years, Patrick has taken a proactive role in certifying that the composite wood substrate materials that it uses to produce products for its customers in the RV marketplace have complied with applicable emission standards developed by the California Air Resources Board (“CARB”). All suppliers and manufacturers of composite wood materials are required to comply with the current CARB regulations.

The Company is certified to sell Forestry Stewardship Council (“FSC”) materials to its customers at certain of its manufacturing branches. The FSC certification provides a link between responsible production and consumption of materials from the world’s forests and it assists our customers in making socially and environmentally responsible buying decisions on the products it purchases.

We believe that we are currently operating in compliance with applicable laws and regulations and have made reports and submitted information as required. The Company believes that the expense of compliance with these laws and regulations with respect to environmental quality, as currently in effect, will not have a material adverse effect on its financial condition or competitive position, and will not require any material capital expenditures for plant or equipment modifications.

Seasonality

Manufacturing operations in the RV and MH industries historically have been seasonal and generally had been at the highest levels when the climate is moderate. Accordingly, the Company’s sales and profits had generally been the highest in the second and third quarters. Seasonal industry trends in the past several years have included the impact related to the addition of major RV manufacturer open houses for dealers to the September/October timeframes, whereby dealers are delaying purchases until new product lines are introduced at these shows. This has resulted in seasonal softening in the RV industry beginning in the mid-third quarter and extending through October, and when combined with our increased concentration in the RV industry, led to a seasonal trend pattern in which the Company achieves its strongest sales and profit levels in the first half of the year.

Employees

As of December 31, 2014, we had 2,799 employees, 2,512 of which were engaged directly in production, warehousing, and delivery operations; 81 in sales; and 206 in office and administrative activities, which includes purchasing, inventory and production control, customer service, human resources, accounting, and information technology, among others. There were no manufacturing plants or distribution centers covered by collective bargaining agreements. Patrick continuously reviews benefits and other matters of interest to its employees and considers its relations with its employees to be good.

Executive Officers of the Company

The following table sets forth our executive officers as of December 31, 2014:

|

Name |

Position |

|

Todd M. Cleveland |

President and Chief Executive Officer |

|

Jeffrey M. Rodino |

Executive Vice President of Sales and Chief Operating Officer |

|

Andy L. Nemeth |

Executive Vice President of Finance, Chief Financial Officer, and Secretary-Treasurer |

|

Courtney A. Blosser |

Vice President of Human Resources |

Todd M. Cleveland (age 46) was appointed Chief Executive Officer in February 2009. Mr. Cleveland assumed the position of President and Chief Operating Officer of the Company in May 2008. Prior to that, Mr. Cleveland served as Executive Vice President of Operations and Sales and Chief Operating Officer from August 2007 to May 2008 following the acquisition of Adorn Holdings, Inc. (“Adorn”) by Patrick in May 2007. Mr. Cleveland spent 17 years with Adorn serving as President and Chief Executive Officer since 2004; President and Chief Operating Officer from 1998 to 2004; Vice President of Operations and Chief Operating Officer from 1994 to 1998; and other leadership roles from 1990 to 1994. Mr. Cleveland has over 24 years of manufactured housing, recreational vehicle, and industrial experience in various operating capacities.

Jeffrey M. Rodino (age 44) was appointed Chief Operating Officer of the Company in March 2013. In addition to this role, Mr. Rodino serves as the Executive Vice President of Sales, a position he has held since December 2011. Prior to that, Mr. Rodino served as Vice President of Sales for the Midwest from August 2009 to December 2011 and was elected an Officer in May 2010. Mr. Rodino also served in a variety of top-level sales and marketing roles after joining Patrick in 2007 and held similar key sales positions during his tenure with Adorn from 2001 until May 2007, when Adorn was acquired by Patrick. Mr. Rodino has over 21 years of experience in serving the recreational vehicle, manufactured housing and industrial markets.

Andy L. Nemeth (age 45) was elected Executive Vice President of Finance, Chief Financial Officer, and Secretary-Treasurer in May 2004. Prior to that, Mr. Nemeth was Vice President-Finance, Chief Financial Officer, and Secretary-Treasurer from 2003 to 2004, and Secretary-Treasurer from 2002 to 2003. Mr. Nemeth was a Division Controller from 1996 to 2002 and prior to that, he spent five years in public accounting with Coopers & Lybrand (now PricewaterhouseCoopers). Mr. Nemeth has over 23 years of manufactured housing, recreational vehicle, and industrial experience in various financial capacities.

Courtney A. Blosser (age 48) was appointed Vice President of Human Resources in October 2009 and elected an Officer in May 2010. Prior to that, Mr. Blosser served in executive level human resource leadership roles that included Corporate Director-Human Resources, Whirlpool Corporation from 2008 to 2009, and Vice President-Human Resources, Pfizer Inc. from 1999 to 2008. Mr. Blosser held human resource leadership roles of increasing responsibility with JM Smucker Company from 1989 to 1999. Mr. Blosser has over 26 years of operations and human resource experience in various industries.

Website Access to Company Reports

We make available free of charge through our website, www.patrickind.com, our Annual Report on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and all amendments to those reports as soon as reasonably practicable after such material is electronically filed with or furnished to the SEC. The charters of our Audit, Compensation, and Corporate Governance and Nominations Committees, our Corporate Governance Guidelines, our Code of Ethics and Business Conduct, and our Code of Ethics Applicable to Senior Executives are also available on the “Corporate Governance” portion of our website. Our Internet website and the information contained therein or incorporated therein are not intended to be incorporated into this Annual Report on Form

10-K.

Additionally, the public may read or copy any materials we file with the SEC at the SEC's public reference room located at 100 F Street N.E., Washington D.C. 20549. The public may obtain information on the operation of the public reference room by calling the SEC at 1-800-SEC-0330. The SEC maintains an Internet site that contains reports, proxy and information statements, and other information regarding issuers that file electronically with the SEC at www.sec.gov.

|

ITEM 1A. |

RISK FACTORS |

The Company’s consolidated results of operations, financial position and cash flows can be adversely affected by various risks related to its business. These risks include, but are not limited to, the principal factors listed below and the other matters set forth in this Annual Report on Form 10-K. All of these risks should be carefully considered.

Economic and business conditions that are beyond our control, including cyclicality and seasonality, and concerns over the sustainability of the economic recovery, have in the past had a significant adverse impact on our operating results, and could negatively impact our operating results in the future.

The three major markets in which we sell our products, RV, MH and industrial, have been characterized by cycles of growth and contraction in consumer demand, and are dependent upon various factors, including the general level of economic activity, consumer confidence, interest rates, access to financing, inventory and production levels, and the cost and availability of fuel. Economic and demographic factors can cause substantial fluctuations in production, which in turn impact sales and operating results. Consequently, the results for any prior period may not be indicative of results for any future period.

Manufacturing operations in the RV and MH industries historically have been seasonal and are generally at the highest levels when the climate is moderate. However, seasonal industry trends in the past several years have been different from prior years, primarily reflecting volatile economic conditions, fluctuations in RV dealer inventories, changing dealer show schedules, interest rates, access to financing, the cost of fuel, and increased demand from RV dealers. Consequently, future seasonal trends may be different from prior years.

In addition, a macroeconomic downturn has historically adversely affected our operating results and could again in the future. Companies in these markets are subject to volatility in production levels, shipments, sales and operating results due to changes in external factors such as general economic conditions, including credit availability, consumer confidence, employment rates, interest rates, inflation and other economic conditions affecting consumer demand, as well as demographic and political changes. We cannot predict the duration of an economic downturn, the timing or strength of a subsequent economic recovery or the extent to which an economic downturn will continue to negatively impact our business, financial condition and results of operations.

We may incur significant charges or be adversely impacted by the consolidation and/or closure of all or part of a manufacturing or distribution facility.

We periodically assess the cost structure of our operating facilities to distribute and/or manufacture and sell our products in the most efficient manner. Based on our assessments and if required by business conditions, we may make capital investments to move, discontinue manufacturing and/or distribution capabilities, or products and product lines, sell or close all or part of additional manufacturing and/or distribution facilities in the future. These changes could result in significant future charges or disruptions in our operations, and we may not achieve the expected benefits from these changes, which could result in an adverse impact on our operating results, cash flows, and financial condition.

The financial condition of our customers and suppliers may deteriorate as a result of weakening conditions in the economy and competitive conditions in their markets.

The markets we serve historically have been highly sensitive to changes in the economic environment. Weakening conditions in the economy could cause the financial condition of our customers and suppliers to deteriorate, which could negatively affect our business through the loss of sales or the inability to meet our commitments. Many of our customers participate in highly competitive markets and their financial condition may deteriorate as a result. A decline in the financial condition of our customers could hinder our ability to collect amounts owed by customers. In addition, such a decline could result in lower demand for our products and services.

Although we have a large number of customers, our sales are significantly concentrated with two customers, the loss of which could have a material adverse impact on our operating results and financial condition.

Two customers in the RV market accounted for a combined 58% of our consolidated net sales in 2014. The loss of either of these customers could have a material adverse impact on our operating results and financial condition. In addition, we do not have long-term agreements with our customers and cannot predict that we will maintain our current relationships with these customers or that we will continue to supply them at current levels.

A significant percentage of the Company’s sales are concentrated in the RV industry, and declines in the level of RV unit shipments or reductions in industry growth, could adversely impact our sales levels to this industry and our operating results.

In 2014, 74% of our net sales were to the RV industry versus 72% in 2013 and 69% in 2012. The increase in the Company’s sales concentration in the RV industry primarily resulted from an increase in RV wholesale unit shipment levels over the last several years, increased RV market penetration by the Company, and the Company’s completion of several RV-related acquisitions in the 2010 to 2014 period. Future declines in RV unit shipment levels or reductions in industry growth could significantly reduce the Company’s revenue from the RV industry and have a material adverse impact on our operating results in 2015 and other future periods.

The manufactured housing and recreational vehicle industries are highly competitive and some of our competitors may have greater resources than we do.

We operate in a highly competitive business environment and our sales could be negatively impacted by our inability to maintain or increase prices, changes in geographic or product mix, or the decision of our customers to purchase our competitors’ products instead of our products or to produce in-house products that we currently produce. We compete not only with other suppliers to the RV and MH producers but also with suppliers to traditional site-built homebuilders and suppliers of cabinetry. Sales could also be affected by pricing, purchasing, financing, advertising, operational, promotional, or other decisions made by purchasers of our products. Additionally, we cannot control the decisions made by suppliers of our distributed and manufactured products and therefore, our ability to maintain our exclusive and non-exclusive distributor contracts and agreements may be adversely impacted.

The greater financial resources or the lower amount of debt of certain of our competitors may enable them to commit larger amounts of capital in response to changing market conditions. Certain competitors may also have the ability to develop innovative new products that could put the Company at a competitive disadvantage. If we are unable to compete successfully against other manufacturers and suppliers to the RV and MH industries, we could lose customers and sales could decline, or we may not be able to improve or maintain profit margins on sales to customers or be able to continue to compete successfully in our core markets.

The cyclical nature of the domestic housing market has caused our sales and operating results to fluctuate. These fluctuations may continue in the future, which could result in operating losses during downturns.

The U.S. housing industry is cyclical and is influenced by many national and regional economic and demographic factors, including:

|

● |

terms and availability of financing for homebuyers and retailers; |

|

● |

overall consumer confidence and the level of discretionary consumer spending; |

|

● |

interest rates; |

|

● |

population and employment trends; |

|

● |

income levels; |

|

● |

housing demand; and |

|

● |

general economic conditions, including inflation, deflation and recessions. |

The RV and MH industries and the industrial markets can be affected by fluctuations in the residential housing market. As a result of the foregoing factors, our sales and operating results can fluctuate, and we expect that they will continue to fluctuate in the future. Moreover, cyclical and seasonal downturns in the residential housing market may cause us to experience operating losses.

Fuel shortages or high prices for fuel have had, and could continue to have, an adverse impact on our operations.

The products produced by the RV industry typically require gasoline or diesel fuel for their operation, or the use of a vehicle requiring gasoline or diesel fuel for their operation. There can be no assurance that the supply of gasoline and diesel fuel will continue uninterrupted or that the price or tax on fuel will not significantly increase in the future. Shortages of gasoline and diesel fuel have had a significant adverse effect on the demand for recreational vehicles in the past and would be expected to have an adverse effect on demand in the future. Rapid significant increases in fuel prices, as we experienced in recent years, appear to affect the demand for recreational vehicles when gasoline prices reach unusually high levels. Such a reduction in overall demand for recreational vehicles could have a materially adverse impact on our revenues and profitability.

We are dependent on third-party suppliers and manufacturers.

Generally, our raw materials, supplies and energy requirements are obtained from various sources and in the quantities desired. While alternative sources are available, our business is subject to the risk of price increases and periodic delays in delivery. Fluctuations in the prices of these requirements may be driven by the supply/demand relationship for that commodity, governmental regulation, economic conditions in other countries, religious holidays, natural disasters, and other events. In addition, if any of our suppliers seek bankruptcy relief or otherwise cannot continue their business as anticipated, the availability or price of these requirements could be adversely affected.

Increases in demand for our products could make it more difficult for us to obtain additional skilled labor, and available capacity may initially not be utilized efficiently.

In certain geographic regions in which we have manufacturing facilities, we have experienced, and could again experience, shortages of qualified employees. If demand continues to increase, we may not be able to increase production to timely satisfy demand, and may initially incur higher labor and production costs, which could adversely impact our financial condition and operating results.

The increased cost and limited availability of certain raw materials may have a material adverse effect on our business and results of operations.

Prices of certain materials, including gypsum, lauan, particleboard, MDF, aluminum and other commodity products, can be volatile and change dramatically with changes in supply and demand. Certain products are purchased from overseas and their availability is dependent upon climate changes, seasonal and religious holidays, political unrest, economic conditions overseas, natural disasters, vessel shipping schedules and port availability. Further, certain of our commodity product suppliers sometimes operate at or near capacity, resulting in some products having the potential of being put on allocation. We generally have been able to maintain adequate supplies of materials and to pass higher material costs on to our customers in the form of surcharges and base price increases where needed. However, it is not certain future price increases can be passed on to our customers without affecting demand or that limited availability of materials will not impact our production capabilities. Our sales levels and operating results could be negatively impacted by changes in any of these items.

We are subject to governmental and environmental regulations, and failure in our compliance efforts or events beyond our control could result in damages, expenses or liabilities that individually or in the aggregate would have a material adverse effect on our financial condition and results of operations.

Our manufacturing processes involve the use, handling, storage and contracting for recycling or disposal of hazardous or toxic substances or wastes. Accordingly, we are subject to various governmental and environmental regulations regarding these substances. In addition, the implementation of new regulations or amendments to existing regulations could significantly increase the cost of the Company’s products. We currently use materials that we believe comply with government regulations. We cannot presently determine what, if any, legislation may be adopted by Congress or state or local governing bodies, or the effect any such legislation may have on our customers or us. In addition, failure to comply with present or future regulations could result in fines or potential civil or criminal liability. Both scenarios could negatively impact our results of operations or financial condition.

Compliance with conflict minerals disclosure requirements will create additional compliance cost and may create reputational challenges.

The SEC adopted rules pursuant to Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act setting forth new disclosure requirements concerning the use or potential use of certain minerals, deemed conflict minerals (tantalum, tin, gold and tungsten), that are mined from the Democratic Republic of Congo and adjoining countries. These requirements necessitate due diligence efforts on our part to assess whether such minerals are used in our products in order to make the relevant required annual disclosures. There will be costs associated with complying with these disclosure requirements, including for diligence to determine the sources of conflict minerals used in our products and other potential changes to products, processes or sources of supply because of such verification activities. The implementation of these rules could adversely affect the sourcing, supply and pricing of materials used in our products. As there may be only a limited number of suppliers offering conflict-free minerals, we cannot be sure that we will be able to obtain necessary conflict minerals from such suppliers in sufficient quantities or at competitive prices. We may also face reputational challenges if we determine that certain of our products contain minerals not determined to be conflict free or if we are unable to sufficiently verify the origins for all conflict minerals used in our products through the procedures we may implement.

The inability to attract and retain qualified executive officers and key personnel may adversely affect our operations.

While we include succession planning as part of our ongoing talent development and management process to help ensure the continuity of our business model, the loss of any of our executive officers or other key personnel could reduce our ability to manage our business and strategic plan in the short-term and could cause our sales and operating results to decline. In addition, our future success will depend on, among other factors, our ability to attract and retain executive management, key employees, and other qualified personnel.

Our ability to integrate acquired businesses may adversely affect operations.

As part of our business and strategic plan, we look for strategic acquisitions to provide shareholder value. Any acquisition will require the effective integration of an existing business and its administrative, financial, sales and marketing, manufacturing, and other functions to maximize synergies. Acquired businesses involve a number of risks that may affect our financial performance, including increased leverage, diversion of management resources, assumption of liabilities of the acquired businesses, and possible corporate culture conflicts. If we are unable to successfully integrate these acquisitions, we may not realize the benefits identified in our due diligence process, and our financial results may be negatively impacted. Additionally, significant unexpected liabilities could arise from these acquisitions.

Increased levels of indebtedness may harm our financial condition and results of operations.

As of December 31, 2014, we had approximately $101.1 million of total debt outstanding under our $165 million revolving credit facility (the “2012 Credit Facility”) that was established pursuant to our current credit agreement, as amended (the “2012 Credit Agreement”).

In certain circumstances, an increase in our level of indebtedness could have adverse consequences on our future operations, including making it more difficult for us to meet our payments on outstanding debt and we may not be able to find alternative financing sources to replace our indebtedness in such an event. Furthermore, such increases could (i) reduce the availability of our cash flow to fund working capital, capital expenditures, acquisitions and other general corporate purposes, and limit our ability to obtain additional financing for these purposes; (ii) limit our flexibility in planning for, or reacting to, and increasing our vulnerability to, changes in our business and the industry in which we operate; (iii) place us at a competitive disadvantage compared to our competitors that have less debt or are less leveraged; and (iv) create concerns about our credit quality which could result in the loss of supplier contracts and/or customers.

Our 2012 Credit Agreement contains various financial performance and other covenants. If we do not remain in compliance with these covenants, our 2012 Credit Agreement could be terminated and the amounts outstanding thereunder could become immediately due and payable.

We have debt outstanding that contains financial and non-financial covenants with which we must comply that place restrictions on us. There can be no assurance that we will maintain compliance with the financial covenants under our 2012 Credit Agreement. These covenants require that we comply with a maximum level of a consolidated total leverage ratio and a minimum level of a consolidated interest coverage ratio under the 2012 Credit Agreement, and adhere to annual capital expenditure limitations as defined by our 2012 Credit Agreement. If we fail to comply with the covenants contained in our 2012 Credit Agreement, the lenders could cause our debt to become due and payable prior to maturity or it could result in our having to refinance the indebtedness under unfavorable terms. If our debt were accelerated, our assets might not be sufficient to repay our debt in full and there can be no assurance that we would be able to refinance any or all of this indebtedness.

Due to industry conditions and our operating results, we have had limited access to sources of capital in the past. If we are unable to locate suitable sources of capital when needed, we may be unable to maintain or expand our business.

We depend on our cash balances, our cash flows from operations, and our 2012 Credit Facility to finance our operating requirements, capital expenditures and other needs. If the general recessionary economic conditions that impacted the economy in 2007-2010 should return in the future, production of RVs and manufactured homes could decline, resulting in reduced demand for our products. A decline in our operating results could negatively impact our liquidity. If our cash balances, cash flows from operations, and availability under our 2012 Credit Facility are insufficient to finance our operations and alternative capital is not available, we may not be able to expand our business and make acquisitions, or we may need to curtail or limit our existing operations.

We have letters of credit representing collateral for our casualty insurance programs and for general operating purposes that have been issued under our 2012 Credit Agreement. The inability to retain our current letters of credit, to obtain alternative letter of credit sources, or to retain our 2012 Credit Agreement to support these programs could require us to post cash collateral, reduce the amount of cash available for our operations, or cause us to curtail or limit existing operations.

Increased levels of inventory may adversely affect our profitability.

Our customers generally do not maintain long-term supply contracts and, therefore, we must bear the risk of advanced estimation of customer orders. We maintain an inventory to support these customers’ needs. Changes in demand, market conditions and/or product specifications could result in material obsolescence and a lack of alternative markets for certain of our customer specific products and could negatively impact operating results.

We could incur charges for impairment of assets, including goodwill and other long-lived assets, due to potential declines in the fair value of those assets or a decline in expected profitability of the Company or individual reporting units of the Company.

A portion of our total assets as of December 31, 2014 was comprised of goodwill, amortizable intangible assets, and property, plant and equipment. Under generally accepted accounting principles, each of these assets is subject to periodic review and testing to determine whether the asset is recoverable or realizable. The events or changes that could require us to test our goodwill and intangible assets for impairment include changes in our estimated future cash flows, changes in rates of growth in our industry or in any of our reporting units, and decreases in our stock price and market capitalization.

In the future, if sales demand or market conditions change from those projected by management, asset write-downs may be required. Significant impairment charges, although not always affecting current cash flow, could have a material effect on our operating results and financial position.

A variety of factors could influence fluctuations in the market price for our common stock.

The market price of our common stock could fluctuate in the future in response to a number of factors, including those discussed below. The market price of our common stock has in the past fluctuated and is likely to continue to fluctuate. Some of the factors that may cause the price of our common stock to fluctuate include:

|

● |

variations in our and our competitors’ operating results; |

|

|

● |

historically low trading volume; |

|

|

● |

high concentration of shares held by institutional investors and in particular our largest shareholder, Tontine Capital (as defined herein); |

|

|

● |

announcements by us or our competitors of significant contracts, acquisitions, strategic partnerships, joint ventures or capital commitments; |

|

|

● |

the gain or loss of significant customers; |

|

|

● |

additions or departures of key personnel; |

|

|

● |

events affecting other companies that the market deems comparable to us; |

|

|

● |

general conditions in industries in which we operate; |

|

|

● |

general conditions in the United States and abroad; |

|

|

● |

the presence or absence of short selling of our common stock; |

|

|

● |

future sales of our common stock or debt securities; |

|

|

● |

announcements by us or our competitors of technological improvements or new products; and |

|

|

● |

the sale by Tontine Capital or its announcement of an intention to sell, all or a portion of its equity interests in the Company. |